Ensuring that your boiler is in compliance with the EPA’s newest emissions regulations is critical to all boiler owners and operators. With proper education on what is required of the boiler MACT, stakeholders can take the appropriate steps to easily meet deadlines and avoid costly fines.

What is Boiler MACT?

The Clean Air Act standards and Boiler MACT (maximum achievable control technology) regulations were issued originally by the EPA and published in the Federal Register in March 2011. Since then, the rules have been re-finalized and tailored to increase flexibility and address concerns held by boiler owners, and reflect the real world operating conditions of specific types of boilers.

The rules were put in place predominately to regulate air pollution from boilers and process heaters, and the major reasoning behind the rules relate directly to maintaining the health of the public. The EPA estimates that for every dollar spent to reduce air pollutants, the public will see $13 to $29 in health benefits, and fewer asthma attacks, heart attacks, and premature deaths.

The requirements of the Boiler MACT applied to equipment that burns coal, oil, biomass, natural gas, or other solid, liquid and gaseous non-waste materials, and different rules apply to different pieces of equipment based upon assigned categories and subcategories.

Final compliance dates for existing major source boilers were January 31, 2016, and existing area source boilers should have been in compliance by March 21, 2014. New sources are to comply by start-up.

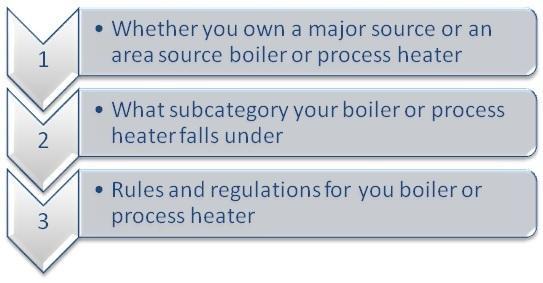

In order to comply with the Boiler MACT, you will need to determine the following:

Step 1: Major Source vs. Area Source

The EPA has estimated that there are 183,000 area source boilers compared to 14,000 major source boilers in the United States. Though emissions from each individual unit may be small, the combined emissions are rather significant and air pollution from boilers and process heaters (particulate matter, carbon monoxide, hydrochloric acid, mercury and trace amounts of heavy metals), can cause a range of health effects including respiratory issues and asthma.

Majority of major source boilers are found in industrial facilities (refineries, chemical and manufacturing plants, and pulp and paper mills), while area source boilers are found more in commercial and institutional facilities (hospitals, educational facilities, and municipal buildings). There are few circumstances, however, where a major source boiler may be found in a commercial facility to provide heat, or an area source boiler is used in an industrial application. An estimated 88% of major source boilers already burn clean fuels, and compliance for these boilers will consist of periodic tune-ups. The remaining 12% will need to meet certain emission standards. In contrast, 99% of area source boilers will require tune-up while less than 1% will need to comply with emissions standards.

To ensure a correct categorization of your boiler, you need to know how many tons per year the boiler emits of a single or combination of air toxics: A major source facility boiler “emits 10 or more tons per year of a single air toxic, or 25 or more tons per year of a combination of air toxics”. If your boiler does not fall into those emission zones, you are working with an area source boiler.

Step 2: Subcategories

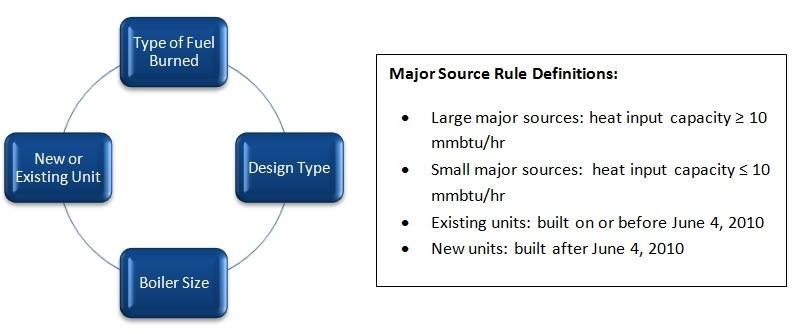

Major source boilers are subcategorized based on four components:

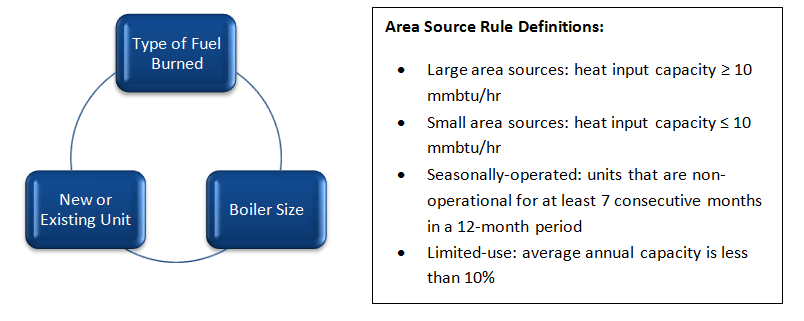

Area source boilers are subcategorized based on three components:

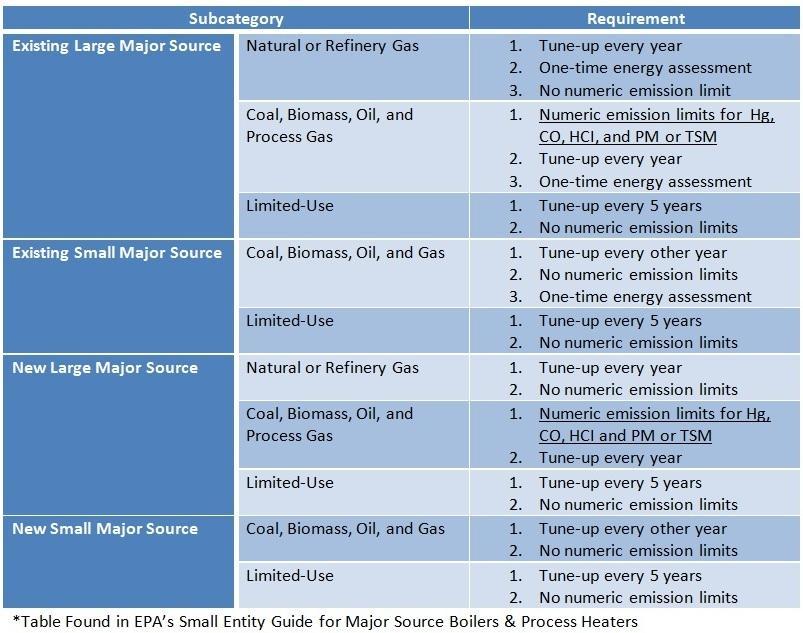

Step 3: Summary of Requirements

Major Source

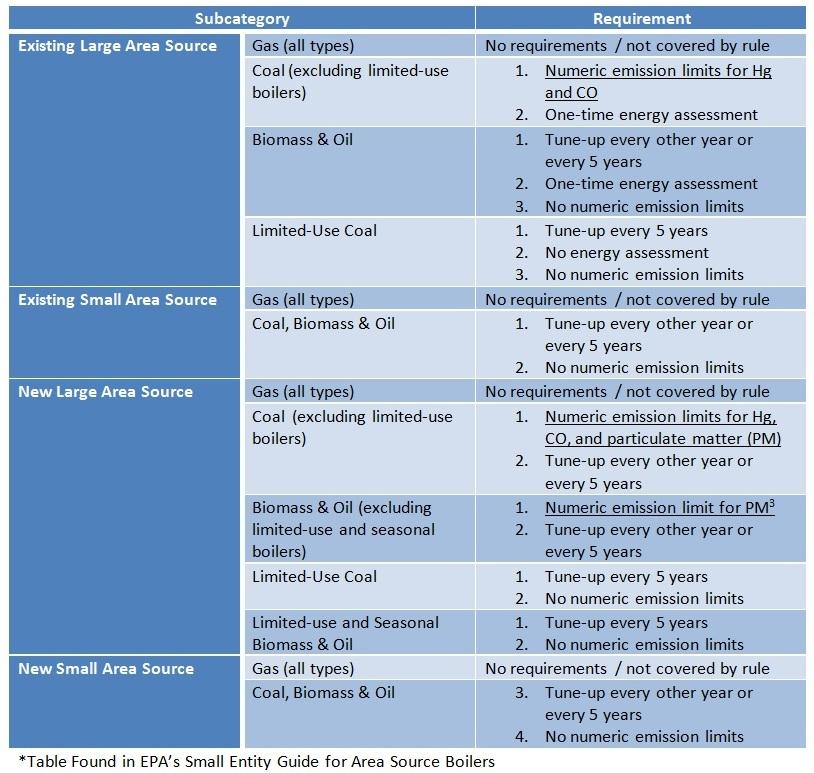

Area Source