With the COVID-19 pandemic upon us, there has been a lot of talk about essential businesses. What is it that actually deems a business essential? In short, businesses that people rely on in everyday life are essential, while nonessential businesses are generally recreational in nature.

Many consumers may not understand the necessity of steam in everyday life, however, steam plays a major role in many industries including hospitals, food processing, refineries, and pulp and paper manufacturing. Let’s dive into exactly how steam is used in some of these processes.

Hospitals

One of the most obvious groups of essential workers right now are those in a hospital, and steam is utilized extensively in all hospital settings. There are five major uses of steam in a hospital: comfort heating, humidification of air, sterilization of surgical instruments and medical waste, laundry, and food preparation.

Food Processing

Steam used by food processors commonly falls into two distinct categories: Clean Steam or Utility Steam. Clean Steam, also known as “sanitary” or “culinary” steam, is typically used for direct injection into a product or to clean and sterilize product contact surfaces. Utility Steam, also referred to as “plant” steam, can be used in most applications that do not involve direct contact with food products or the surfaces that the food might contact. It is often utilized to supply energy for heating, cooking, or mechanical work.

Some other examples of where steam is typically utilized in food processing is the tomato canning process, deodorizing cocoa butter, puffing up cereal, and sanitization of yogurt cups.

Electricity Generation

Most of the electricity generated in the United States is from electric power plants that use a turbine to drive electricity generators, and many of these turbines are driven by steam. Steam turbines use high-pressure steam to rotate the blades of a turbine and create mechanical or rotational energy. As the steam turbine spins, the generator spins and creates electricity.

Pulp & Paper

Steam is used heavily in the production of paper products because energy drives the papermaking process. In fact, it is estimated nationally that steam accounts for approximately 43% of the total energy demand at a paper facility.

Most paper mills have a steam turbine to generate electricity. Steam is also used to cook wood chips and cook fibers for improved sheet strength, to evaporate moisture from pulp, to heat rotating dryer drums to dry the paper stock, and to heat chemicals for other processes. The steam from a boiler is also commonly used in other locations of the mill, like heat exchangers, steam-traced piping, and stock chests. Due to its usefulness, steam is the primary input used to evaporate moisture from a sheet, allowing for desirable and profitable sheet characteristics to be created.

Petroleum Refining

Petroleum refining is an energy-intensive process, with energy accounting for approximately 50% of refining costs. Steam is used in many ways in a refinery and is necessary to keep plants running. Some uses include:

- - Steam turbines for electricity generation and running pumps and compressors.

- - Steam tracing and jacketing to keep viscous processes fluid in pipes.

- - As a heating source to break up oils and distribute for the manufacturing of different products.

- - As a heating source for lube oil systems for large pieces of equipment.

- - As a heating source for reboilers.

- - Plant cleanup.

- - Stripper column injection to aid in stripping separation of different processes.

- - Minor leak suppression by use of steam lances.

- - Steam flares to aid in complete combustion of processes.

Chemical Processing

Steam also plays a large role in chemical processing and is used as both a process fluid and a utility. Common uses include process heating, power generation, atomization, cleaning and sterilization, moisturization, and humidification. Because it is so versatile, there are some major advantages to using steam in chemical processing:

- Control. By controlling the pressure of steam, you can control the temperature at which the heat is released. Having good control over the temperature is necessary in a number of chemical processes.

- Efficiency. Steam is an efficient heat source because it has a high output per mass of utility at a constant temperature.

- Safety. It is non-flammable, non-toxic, and inert to several process fluids.

Although steam is often hidden from our daily lives, it is the most effective way to transfer heat or energy and offers unique features that you just cannot duplicate with other systems. The simplicity and adaptability of steam makes it a reliable medium and first choice for many processing operations.

Nationwide Boiler takes pride in supporting many essential businesses with a reliable source of steam, whether for temporary or permanent use. As our own Walter Heussmann put it, “The heartbeat of America is driven by steam. The power industry, oil and gas, chemical, hospitals, food and beverage…. We are here to keep America going.”

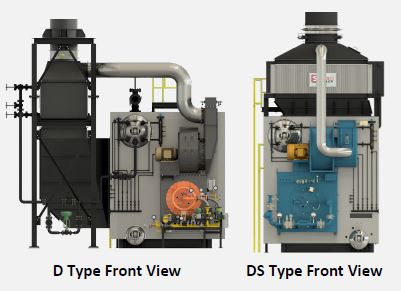

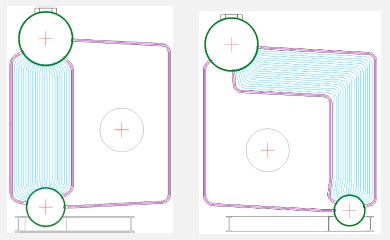

The configuration for this type of boiler is similar to the D-Type, with one upper steam drum, one lower drum, and one convection bank. One of the main differences lies in the convection bank flow area (the bank of tubes that provide convection heat transfer), which is much larger and utilizes upside-down L shaped tubes. This larger area means a reduced boiler pressure drop on the flue gas side. A smaller fan is required, reducing both cost and energy usage.

The configuration for this type of boiler is similar to the D-Type, with one upper steam drum, one lower drum, and one convection bank. One of the main differences lies in the convection bank flow area (the bank of tubes that provide convection heat transfer), which is much larger and utilizes upside-down L shaped tubes. This larger area means a reduced boiler pressure drop on the flue gas side. A smaller fan is required, reducing both cost and energy usage.